. Wikipedia § Masamune, Honjō Masamune, heritage status (Law for the Protection of Cultural Properties)

. Wikipedia § List of National Treasures of Japan (crafts: swords)

Quick dictionary to help you choose the right katana: homogeneous steel, Maru, damascus, 1045, 1060, 1095, complex forging (Kobuse, Soshu Kitae, Shihomizue...), true tempering line, Hamon...

Publication date :

Last update :

Homogeneous forging (Maru): this is the simplest form, using a single type of steel, e.g. 1045.

The lower cost of this type of manufacture explains its high proportion in current katana blade production. Although homogeneous, a Maru forge using 1095 steel will produce an excellent quality/price compromise.

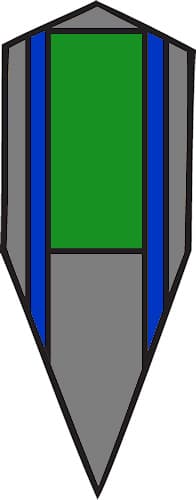

Kobuse forge (sandwich): two steels are used. At the core, a hard steel (or soft steel, depending on its carbon content, e.g. 0.45% for a 1045) is surrounded by an extra-hard steel (which may be a 1060 or 1095).

By definition, sandwich forging entails a risk at the time of manufacture, as the two steels have to wrap around each other. The weld between the two materials is therefore a point of fragility that must be mastered by an experienced blacksmith.

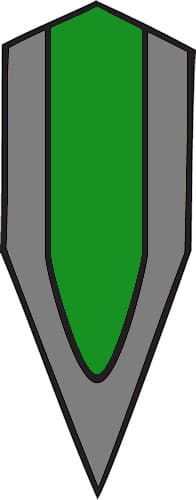

Soshu-Kitae forge: three steels are used, from "soft" to extra-hard, from the core to the surface of the blade.

Sandwich forging with several steels combines the hardness of an extra-hard steel (1095, for example) with the relative flexibility of a "softer" steel (such as 1045). However, the choice of steel and type of forging can be greatly improved with differential hardening.

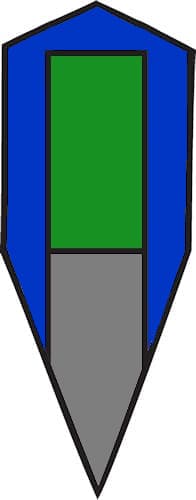

Shihomizue forge: three steels are also used, from the "softest" (green) to the extra-hard (gray), from the core to the edge of the blade.

This type of forging produces a hard edge, ideal for penetrating and cutting the target. The softer steel core and sheath provide the suppleness needed for cutting. The clay tempe accentuates this combination of softness and hardness.

Damascus forge (damascus or laminated blade): damascus steel refers to two types of forge. The first uses a steel called wootz. Sourced from India and the Middle East, it is renowned for its quality. Unique patterns are present on the surface of the steel. The term also refers to heterogeneous steels made from several grades of steel welded together and forged to produce more or less complex patterns. This material, known as "wrought Damascus steel", borrows the name from the historic metal by misuse of language because of its superficial resemblance to wootz Damascus steel.

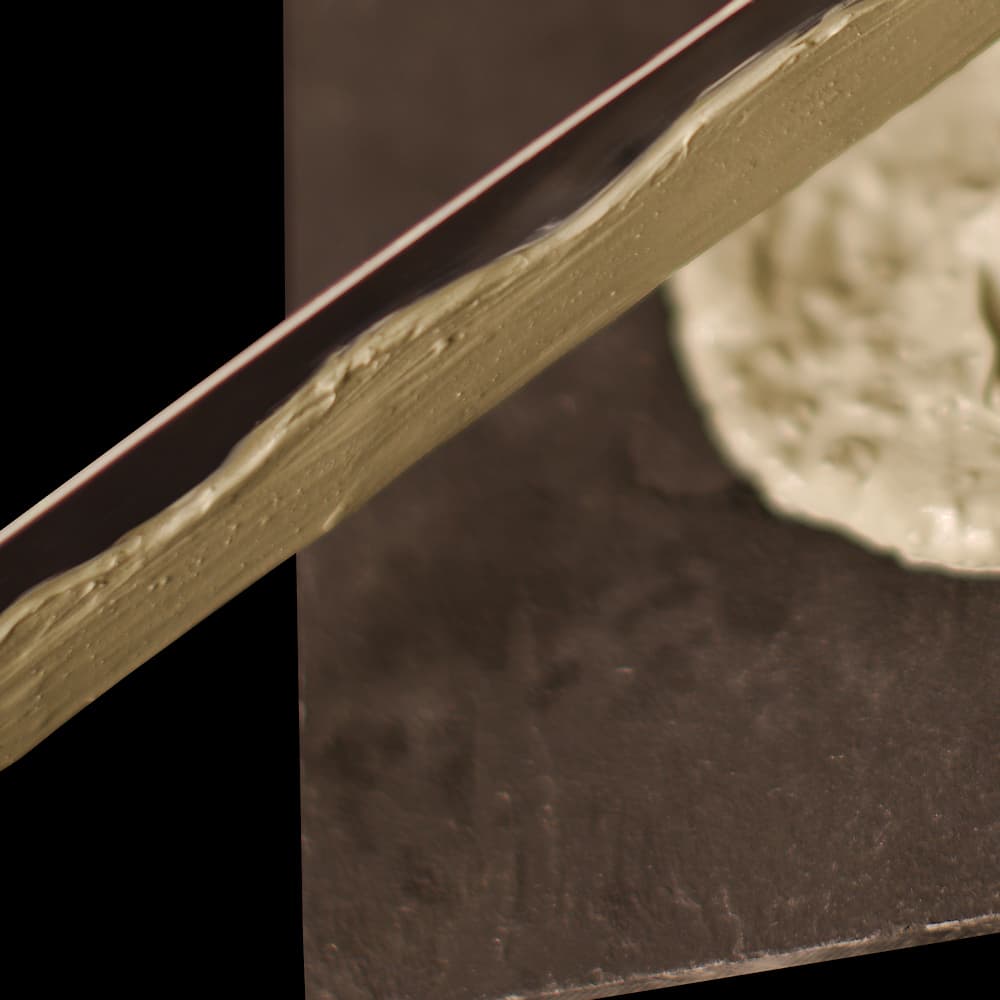

To improve the steel's softness/hardness characteristics, a refractory material such as clay is used to protect the areas we wish to soak less (softer). In this way, the back of the blade can be covered with clay during the heat-treatment operation, resulting in excellent hardness of the blade edge (Ha 刃) while maintaining the flexibility of the back (Mune 棟). This technique creates a characteristic hardening line (Hamon 刃文). This is known as clay or differential quenching.

The temper line will appear at the moment of polishing, as a subtle boundary between the tempered (and hard) area and the area protected by the clay (less tempered and therefore softer). Entry-level or decorative katanas reproduce a false temper line by using a grinding wheel (mechanical surface action).

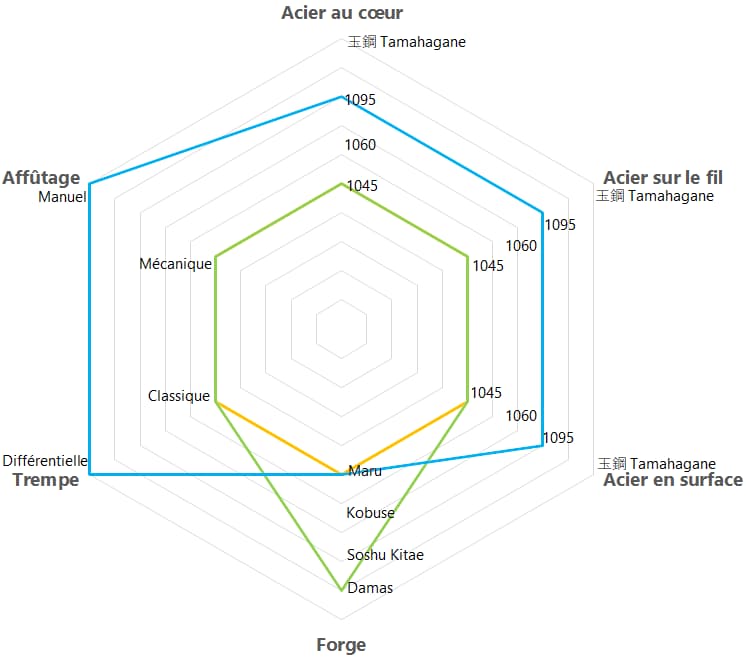

On this graph, you can see three curves:

In yellow, a Maru 1045 steel.

Example of a katana: "The Last Samurai" sharpened katana (ref. 0471).

In green, Damascus steel (laminated forge).

Example of katana: sharpened katana Kokuyō (黒夜, black night), damascus blade, black mount (ref. 0480)

In blue, a Maru 1095 (extra-hard) steel with differential clay hardening and hand sharpening.

Example of katana: Sacred Earth katana (聖地, Seichi), sharpened 1095 blade, genuine hamon, brown braiding (ref. 0481)

SharpKatana...see more

SharpKatana...see more

SharpKatana...see more

SharpKatana...see more

SharpKatana...see more

Secure payment: your choice

PayPalwith or without account (CB)

Scalapay: 3 times free of charge

Cheque or bank transfer (contact us)

Trust

. French company

. Integrated warehousing and logistics

. No customs duties

. Studio and engraving workshop

. Shipment within 48 working hours

. Delivery in mainland France and Europe (Euro zone: Germany, Austria, Belgium, Cyprus, Croatia, Spain, Estonia, Finland, Greece, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Portugal, Slovakia, Slovenia); D.O.M. / T.O.M.: on quotation. Please contact us for further information.

. 14-day right of withdrawal

Delivery

Your Colissimo tracking space allows you to track and manage the delivery of your parcels.

Useful links

Customer reviews

Terms & Conditions

Frequently asked questions (F.A.Q.)

Cancellation form

Personal data R.G.P.D.